Wood-pulp Paper: Difference between revisions

Created page with "== Wood-Pulp Paper == Wood-pulp paper is paper that is crafted with "wood pulp, particularly wood logged from the pine forests of North America."<ref>---. ''The Book in Society: An Introduction to Print Culture''. Broadview Press, 2013.</ref> Essentially, wood-pulp paper is plant-based paper, made from a combination of tree wood, bark, and pulp. === History of Wood-Pulp Paper === Wood-pulp paper began to be made and used around the middle of the nineteenth century. Dur..." |

(No difference)

|

Latest revision as of 13:38, 5 December 2025

Wood-Pulp Paper

Wood-pulp paper is paper that is crafted with "wood pulp, particularly wood logged from the pine forests of North America."[1] Essentially, wood-pulp paper is plant-based paper, made from a combination of tree wood, bark, and pulp.

History of Wood-Pulp Paper

Wood-pulp paper began to be made and used around the middle of the nineteenth century. During this time, because of the growing demand for paper, the resources that were already being used to make paper, such as linen, were becoming depleted. Therefore, wood-pulp began to be made in order to fill quotas for book-printing.

How is Wood-Pulp Paper Used Today?

Wood-pulp is no longer commonly used in book production, but it can still be found in inexpensive printing paper, coffee filters, paper bags, and toilet paper.[2]

Disadvantages of Using Wood-Pulp Paper:

According to The Book in Society: An Introduction to Print Culture by Solveig C. Robinson, there are a few reasons why using wood-pulp paper isn't always the easiest or wisest way to print. Firstly, "most plant-based paper was coarser than cloth-based papers, because it was difficult to break down the woody fibers sufficiently by hand-pounding. This rendered plant-based papers difficult to use for either manuscript or printed documents, because the surface was uneven."[4] This obviously poses a large issue, and this is a reason why using wood-pulp paper is uncommon. On top of that, "even when using traditional whitening agents such as lime or chalk, most plant-based paper still turned out darker in color than silk, flax, or linen-based papers. It was therefore difficult to assure sufficient contrast between the writing surface and the ink."[5] Due to all of these factors combined, the conclusion can be made that using wood-pulp paper is most likely not as efficient as printing in different mediums.

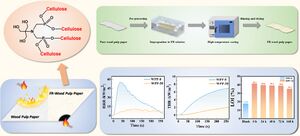

Additionally, according to Polymer Degradation and Stability, Volume 215, "Wood pulp paper (WPP) is an exemplary substrate material, yet its flammability impedes the widespread application in diverse functional fields."[6] Essentially, this means that due to wood-pulp paper's chemical makeup (when it is unaltered), it is highly flammable. This prevents it from being used in some fields.

How Can the Disadvantages of Wood-Pulp Paper be Remedied?

In the article from Polymer Degradation and Stability, researchers shared a chemical alteration that they tested in order to decrease the flammability of wood-pulp paper. An excerpt from the report is pasted below:

"X-ray photoelectron spectroscopy (XPS), Fourier transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM) and Energy Dispersive Spectroscopy (EDS) analysis demonstrated that AMPAP-NH4+ was directly linked to cellulose fibers via POC bonds, effectively introducing P and N elements into the WPP without altering the surface morphology of the fibers. Results from thermogravimetric analysis, vertical burning test, limiting oxygen index test, cone calorimeter test and thermogravimetric-Fourier infrared spectrometer test demonstrated that the treated WPP exhibited outstanding flame retardancy. The peak heat release rate (pHRR) and total heat release (THR) values decreased by 80.8% and 70.9%, respectively, and the limiting oxygen index (LOI) increased to 41.4%."[7]

In short, this passage states that after running a variety of tests on the makeup of wood-pulp, researchers concluded that the property that made wood-pulp so flammable was directly linked to the cellulose fibers within the contents. After treating the cells and makeup through various experiments and continual testing, researchers observed that the treated product displayed increased durability under heated conditions.

- ↑ ---. The Book in Society: An Introduction to Print Culture. Broadview Press, 2013.

- ↑ paper-world.com - Birkner GmbH & Co. KG and Birkner-Redaktion: service@paper-world.com. “Pulp in Paper Production: Foundation for High-Quality Paper Products.” paper-world.com, 14 Mar. 2025, www.paper-world.com/en/newsdetail/importance-of-pulp-in-paper-production.

- ↑ Site Protection - Verification Required. www.lib.uchicago.edu/collex/exhibits/under-covers/conservation-modern-materials-photoreproductions/wood-pulp-paper.

- ↑ ---. The Book in Society: An Introduction to Print Culture. Broadview Press, 2013.

- ↑ ---. The Book in Society: An Introduction to Print Culture. Broadview Press, 2013.

- ↑ Sun, Haowen, et al. “A Highly Efficient, Colorless Phosphorus–nitrogen Synergistic Flame Retardant for Durable Flame Retardancy in Wood Pulp Paper.” Polymer Degradation and Stability, vol. 215, p. 110468, doi:10.1016/j.polymdegradstab.2023.110468.

- ↑ Sun, Haowen, et al. “A Highly Efficient, Colorless Phosphorus–nitrogen Synergistic Flame Retardant for Durable Flame Retardancy in Wood Pulp Paper.” Polymer Degradation and Stability, vol. 215, p. 110468, doi:10.1016/j.polymdegradstab.2023.110468.

- ↑ Sun, Haowen, et al. “A Highly Efficient, Colorless Phosphorus–nitrogen Synergistic Flame Retardant for Durable Flame Retardancy in Wood Pulp Paper.” Polymer Degradation and Stability, vol. 215, p. 110468, doi:10.1016/j.polymdegradstab.2023.110468.