Photolithography: Difference between revisions

AubreeHamer (talk | contribs) No edit summary |

AubreeHamer (talk | contribs) I added an image and its citation |

||

| (3 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

Photolithography is a process used in the publishing industry, involving light to transfer patterns onto substrates when manufacturing integrated circuits. The process dates back to 1796 when lithography was used as a low-cost method to publish theatrical works by Alois Senefelder. It was later developed in 1959 by Mohamed M. Atalla which is the process that is currently used. Photolithography is a more convenient process than typographers. In his book, Robinson writes, “The original purpose of type was simply copying. The job of the typographer was to imitate the scribal hand in a form that permitted exact and fast replication. Dozens, then hundreds, then thousands of copies were printed in less time than a scribe would need to finish one. This excuse for setting texts in type has disappeared. In the age of photolithography, digital scanning and offset printing, it is as easy to print directly from handwritten copy as from text that is typographically composed” (Robinson 18). <ref> Robinson, Solveig C. The Book in Society : An Introduction to Print Culture. Broadview Press, 2014. </ref> | Photolithography is a process used in the publishing industry, involving light to transfer patterns onto substrates when manufacturing integrated circuits. The process dates back to 1796 when lithography was used as a low-cost method to publish theatrical works by Alois Senefelder. It was later developed in 1959 by Mohamed M. Atalla which is the process that is currently used. Photolithography is a more convenient process than typographers. In his book, Robinson writes, “The original purpose of type was simply copying. The job of the typographer was to imitate the scribal hand in a form that permitted exact and fast replication. Dozens, then hundreds, then thousands of copies were printed in less time than a scribe would need to finish one. This excuse for setting texts in type has disappeared. In the age of photolithography, digital scanning and offset printing, it is as easy to print directly from handwritten copy as from text that is typographically composed” (Robinson 18). <ref> Robinson, Solveig C. The Book in Society : An Introduction to Print Culture. Broadview Press, 2014. </ref> | ||

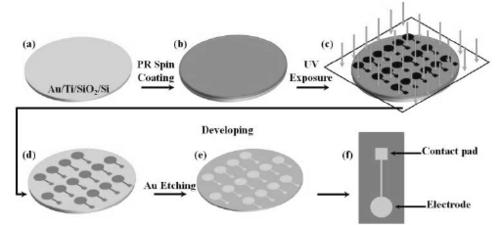

[[File:Photolithography-process.png|thumb|500x500px|This is an overview and visual for the photolithography process. <ref>“Phosphate Sensors Based on Co-Cu Electrodes Fabricated with a Sacrificial Glass Fiber Paper Template.” ''Research Gate'', Nov. 2015, [https://www.researchgate.net/figure/Photolithography-process_fig1_293649478 www.researchgate.net/figure/Photolithography-process_fig1_293649478]. Accessed 8 Nov. 2025.</ref>]] | |||

== Photolithography Process == | == Photolithography Process == | ||

There are 8 steps in the Photolithography process including: substrate preparation, photoresist application, soft bake, exposure, development, hard bake, etching, and photoresist removal. | There are 8 steps in the Photolithography process including: substrate preparation, photoresist application, soft bake, exposure, development, hard bake, etching, and photoresist removal. | ||

The substrate first needs to be cleaned and prepared by removing any contaminates, typically by giving a silicon wafer a series of chemical baths. Then, a spin-coating process applies photoresist to the wafer, evenly dispersing the photoresist. A hotplate is then used to bake the wafer in order to remove excess solvent while keeping the photoresist intact. The photoresist then needs to be prepped for receiving the pattern or image that will be transferred on. In order to do this, the photoresist is exposed to the photomask containing the pattern and by aligning the photomask with the wafer. Certain areas of the photoresist must be removed to create the desired pattern or image. This is done by placing the wafer in a developer solution. The wafer must be baked a second time to harden it and allow the photoresist to remain attached to the wafer. The etching process transfers the pattern by using either wet or dry methods. This transfers the pattern to a different layer. The last step is to remove the rest of the photoresist in order for the pattern to be completely visible on the other layer. A solvent or plasma ashing process is typically used for this last step. <ref> Ems. “Photolithography Technology – the Most Useful Introduction.” EMS, 13 Nov. 2024, electronicmanufacturingservice.org/photolithography-technology-the-most-useful-introduction/. Accessed 09 Sept. 2025. | The substrate first needs to be cleaned and prepared by removing any contaminates, typically by giving a silicon wafer a series of chemical baths. Then, a spin-coating process applies photoresist to the wafer, evenly dispersing the photoresist. A hotplate is then used to bake the wafer in order to remove excess solvent while keeping the photoresist intact. The photoresist then needs to be prepped for receiving the pattern or image that will be transferred on. In order to do this, the photoresist is exposed to the photomask containing the pattern and by aligning the photomask with the wafer. Certain areas of the photoresist must be removed to create the desired pattern or image. This is done by placing the wafer in a developer solution. The wafer must be baked a second time to harden it and allow the photoresist to remain attached to the wafer. The etching process transfers the pattern by using either wet or dry methods. This transfers the pattern to a different layer. The last step is to remove the rest of the photoresist in order for the pattern to be completely visible on the other layer. A solvent or plasma ashing process is typically used for this last step. <ref> Ems. “Photolithography Technology – the Most Useful Introduction.” EMS, 13 Nov. 2024, [https://electronicmanufacturingservice.org/photolithography-technology-the-most-useful-introduction/ electronicmanufacturingservice.org/photolithography-technology-the-most-useful-introduction/]. Accessed 09 Sept. 2025. | ||

</ref> | </ref> | ||

== Lithography == | |||

Lithography and photolithography are similar to one another, but lithography is used for text rather than images or patterns. It’s a process that is ink-based, using a flat plate rather than individual raised pieces of type. In the lithography process, the only key difference from that of photolithography is that the text is transferred onto paper. In the photolithography process, the substrate is the final result. In their article, Julia A. Rosenthal writes, “Lithography differs from photocopying in that plates must be created and ink applied before prints can be made. Photocopying uses a process known as [[xerography]], in which a tube-shaped drum charged with light-sensitive material picks up an image directly from a source” (Rosenthal para. 3). <ref> “Lithography | Research Starters | EBSCO Research.” EBSCO, 2024, [https://www.ebsco.com/research-starters/visual-arts/lithography#full-article www.ebsco.com/research-starters/visual-arts/lithography#full-article.] Accessed 8 Nov. 2025. </ref> | |||

== Publishing Industry == | |||

Photolithography is important to the publishing industry as it allows a more efficient way for images to be copied and printed for newspapers, magazines, books, and more. Lithography is also important since it provides a more efficient way for text to be printed and transferred. Both lithography and photolithography have been crucial for the innovation of printmaking in today’s world. | |||

== Notes == | == Notes == | ||

Latest revision as of 11:42, 8 November 2025

Photolithography is a process used in the publishing industry, involving light to transfer patterns onto substrates when manufacturing integrated circuits. The process dates back to 1796 when lithography was used as a low-cost method to publish theatrical works by Alois Senefelder. It was later developed in 1959 by Mohamed M. Atalla which is the process that is currently used. Photolithography is a more convenient process than typographers. In his book, Robinson writes, “The original purpose of type was simply copying. The job of the typographer was to imitate the scribal hand in a form that permitted exact and fast replication. Dozens, then hundreds, then thousands of copies were printed in less time than a scribe would need to finish one. This excuse for setting texts in type has disappeared. In the age of photolithography, digital scanning and offset printing, it is as easy to print directly from handwritten copy as from text that is typographically composed” (Robinson 18). [1]

Photolithography Process

There are 8 steps in the Photolithography process including: substrate preparation, photoresist application, soft bake, exposure, development, hard bake, etching, and photoresist removal.

The substrate first needs to be cleaned and prepared by removing any contaminates, typically by giving a silicon wafer a series of chemical baths. Then, a spin-coating process applies photoresist to the wafer, evenly dispersing the photoresist. A hotplate is then used to bake the wafer in order to remove excess solvent while keeping the photoresist intact. The photoresist then needs to be prepped for receiving the pattern or image that will be transferred on. In order to do this, the photoresist is exposed to the photomask containing the pattern and by aligning the photomask with the wafer. Certain areas of the photoresist must be removed to create the desired pattern or image. This is done by placing the wafer in a developer solution. The wafer must be baked a second time to harden it and allow the photoresist to remain attached to the wafer. The etching process transfers the pattern by using either wet or dry methods. This transfers the pattern to a different layer. The last step is to remove the rest of the photoresist in order for the pattern to be completely visible on the other layer. A solvent or plasma ashing process is typically used for this last step. [3]

Lithography

Lithography and photolithography are similar to one another, but lithography is used for text rather than images or patterns. It’s a process that is ink-based, using a flat plate rather than individual raised pieces of type. In the lithography process, the only key difference from that of photolithography is that the text is transferred onto paper. In the photolithography process, the substrate is the final result. In their article, Julia A. Rosenthal writes, “Lithography differs from photocopying in that plates must be created and ink applied before prints can be made. Photocopying uses a process known as xerography, in which a tube-shaped drum charged with light-sensitive material picks up an image directly from a source” (Rosenthal para. 3). [4]

Publishing Industry

Photolithography is important to the publishing industry as it allows a more efficient way for images to be copied and printed for newspapers, magazines, books, and more. Lithography is also important since it provides a more efficient way for text to be printed and transferred. Both lithography and photolithography have been crucial for the innovation of printmaking in today’s world.

Notes

- ↑ Robinson, Solveig C. The Book in Society : An Introduction to Print Culture. Broadview Press, 2014.

- ↑ “Phosphate Sensors Based on Co-Cu Electrodes Fabricated with a Sacrificial Glass Fiber Paper Template.” Research Gate, Nov. 2015, www.researchgate.net/figure/Photolithography-process_fig1_293649478. Accessed 8 Nov. 2025.

- ↑ Ems. “Photolithography Technology – the Most Useful Introduction.” EMS, 13 Nov. 2024, electronicmanufacturingservice.org/photolithography-technology-the-most-useful-introduction/. Accessed 09 Sept. 2025.

- ↑ “Lithography | Research Starters | EBSCO Research.” EBSCO, 2024, www.ebsco.com/research-starters/visual-arts/lithography#full-article. Accessed 8 Nov. 2025.